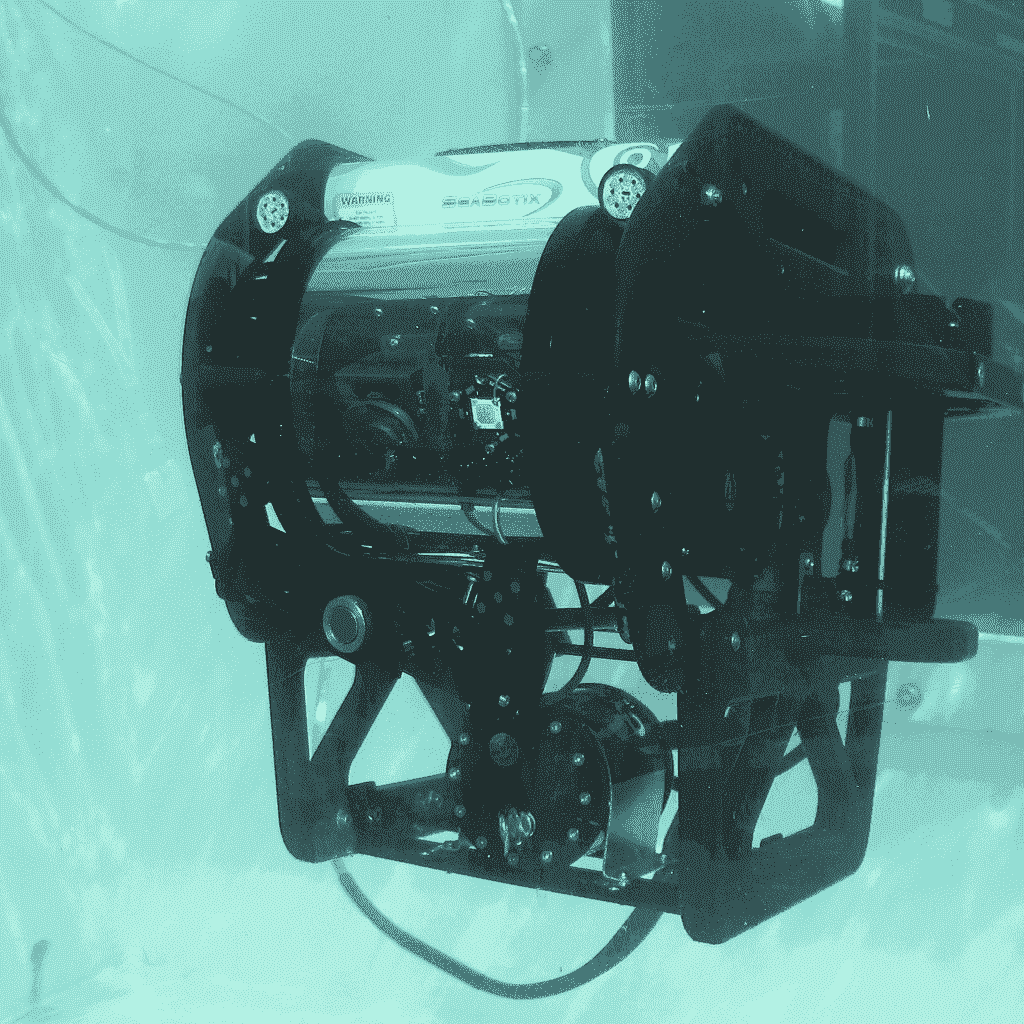

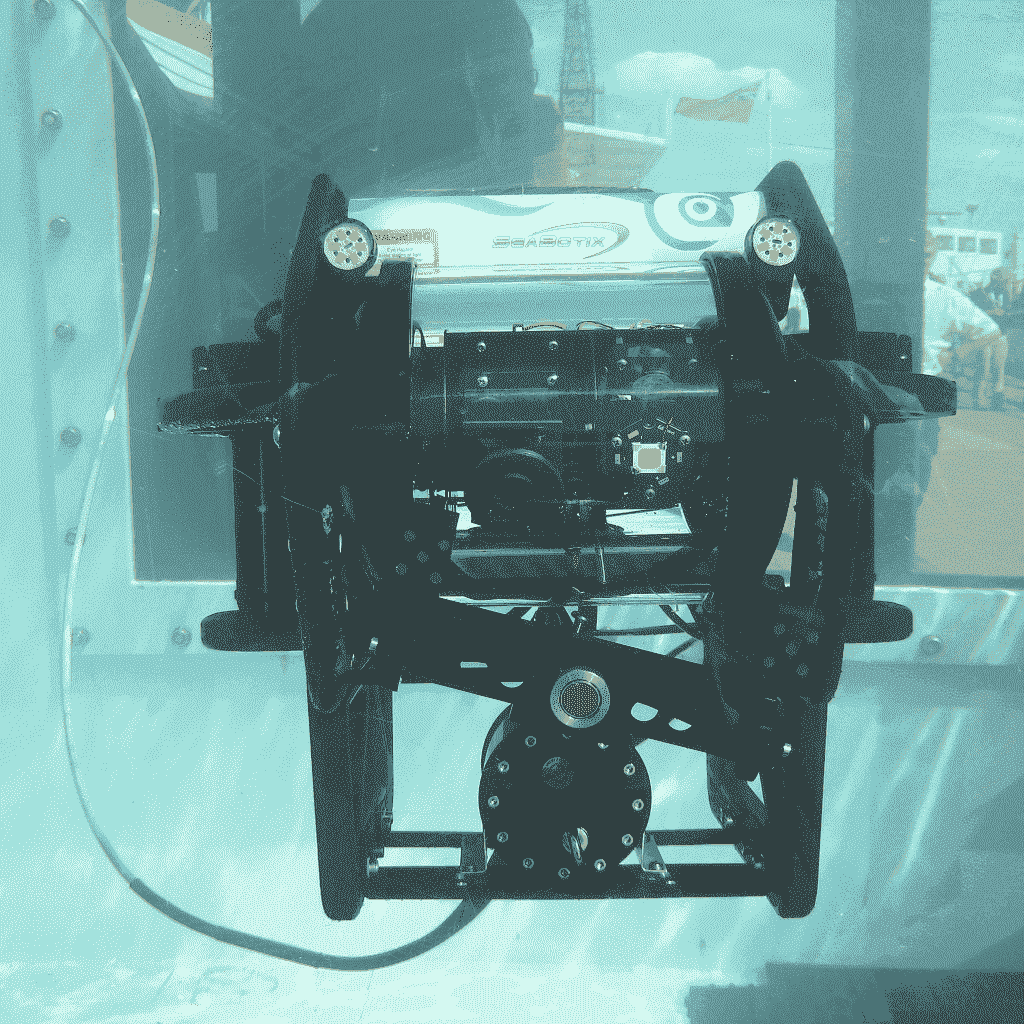

Cygnus ROV Mountable

Subsea Ultrasonic Thickness Tester

Key Features of the Cygnus ROV Mountable Tester

- Multiple-Echo mode for accurate, through-coat measurements as specified by Classification Societies

- Supplied with CygLink software to display and process measurements on a computer at the surface

- Selectable Deep-Coat mode ignoring coatings up to 20mm thick

- Fitted with a safety Pressure Relief Valve and Securing Eye

- Easy calibration at the surface via CygLink software or TopSide Repeater (TSR) unit

- Removable end plate for full serviceability

- Wet mateable ‘MC’ style underwater connectors.

- Optional Topside Repeater (TSR) unit allowing readings to be displayed remotely and superimposed onto ROV’s camera screen

- Optional purpose-built ROV probe handlers for optimal alignment.

Cygnus-Pioneered Multiple Echo Technique

- Measures remaining metal thickness on corroded and coated structures

- All measurements are error checked using 3 return echoes to give repeatable, reliable results

- Accepted by all major classification societies

- Greatly reduces inspection time and costs

- Echo strength indicator to aid measurement.

CygLink Computer Software

CygLink is a Windows® application that allows remote viewing, control and data logging of the ROV tester. The software can generate survey reports in PDF or export to a CSV file. Designed for Windows® 7 and above.

The latest version of CygLink software is available to download from ‘Software Downloads’.

| Materials | Velocities between 2,000 and 7,000 m/s |

| Measurement Range in Steel | 1 – 250 mm depending on selected probe and configuration, material and temperature |

| Accuracy | ±0.1 mm or 0.1% of thickness measurement, whichever is greatest, when calibrated in accordance with Cygnus Instruments calibration procedure |

| Resolution | 0.1 or 0.05 mm (selectable) |

| Probe Options | Single crystal probes |

| Power | 7.0 – 30 V DC @ 150 mA (max) |

| Size | 127 x 90 mm |

| Weight in Air | 900 g |

| Operating Temp. | -10°C to +50°C |

| Testing | Depth rated to 500 meters |

| Communication | RS-422, Simplex Single Pair or RS-232 TXD 2400 or 9600 Baud (selectable via DIP switches) |

| Standards | Designed for EN 15317 |

| Compliance | CE, UKCA, RoHS |

| Warranty | 3 years on tester 6 months on probe |

Instrument unit, ROV power and data cable with flying leads, membrane couplant, ‘K3’ RS-422/485 to RS-232 converter, RS-232 to USB converter, ROV probe cable with heavy duty remote probe, USB flash drive CygLink installation and operating manual in PDF format, ROV power and data test cable and connectors, spare O-rings, spare membranes, membrane locking ring key, test block, spare 1A fuses, allen key and silicone grease sachets.

| Weight | 5 kg |

| Kit | Cygnus ROV Mountable Gauge Standard Kit – 2K Model with 2.25MHz 13mm Standard Probe, Cygnus ROV Mountable Gauge Standard Kit – 2K Model – WITHOUT PROBE |

2 reviews for Cygnus ROV Mountable

James M.

May 16, 2015 1:03 PM

This is to testify that over the last 23 years of working offshore I have come across Cygnus instruments both as a Diver and as an ROV supervisor.

As a diver I held a CSWIP 3.2u Subsea inspection qualification for 10 years.

During the last 13 years I have had occasion to be involved with the ROV mountable systems on two occasions. In both instances the probe and Subsea housing were fitted to work class vehicles. The systems were able to take UT readings to client satisfaction.

On one setup we attached the probe to a 7 function manip (T3) which gave us extra options whilst trying to take readings on non vertical or variable angled faces.

The system is designed to ensure that it will only display correct readings. In other words you either get a correct reading or no reading at all.

Reading through hard marine growth is not practical. Reading through soft marine growth or protective coatings presents no real issues.

From operational experience am aware that all readings eliminate the coating thickness so only the true metal thickness is displayed.

Should I need to specify an Ultrasonic digital thickness gauge for Subsea ROV use I would choose either the Cygnus -1000m* or the -3000m* ROV mountable gauge depending on operational depth.

The -3000m* unit of course will work shallow or deep, so is probably a better all round option for future project use.

*1000m and 3000m are previous models. Available now is the 2000m model.

George G.

Nov 04, 2020 1:01 PM

I have used Cygnus UT systems for many years and to me they deliver what’s required for quick and reliable results. As we move even more towards ROV based operations, having a cost-effective wall thickness capability is a key component in our service offering- and Cygnus does just that!