Ultrasonic Thickness Testing

If you’ve been searching for top of the range ultrasonic thickness testing equipment, then you’ve come to the right place. Here at Cygnus Instruments, we are a leading company in the ultrasonic thickness gauge trade and have a broad range of equipment available for purchase. Talk to our team today to discover what sets us apart as the ideal choice for thickness measuring products. Give us a call now on +1 410-267-9771, or send an email to sales@cygnusinstruments.com.

Why Do You Need an Ultrasonic Thickness Tester?

There are many industries in which ultrasonic thickness testing may be required. Whether you work with oil pipelines or in more hazardous environments, you’d be surprised at just how useful a thickness gauge can be. This equipment is available in a range of different models and modes, all of which are best suited to specific types of material. However, a thickness gauge is only as good as the company that has produced it, which is why it is necessary to find a reliable supplier.

It is for this reason that we at Cygnus Instruments are the best choice for businesses in need of a UT thickness tester. For years we have been pioneers in the industry with our innovative technology putting us a step above similar companies. The dedication of our team to produce products of the highest quality is unparalleled, and this shows through the equipment we have to offer. Continue reading to discover exactly how our ultrasonic thickness gauges work.

How Does Ultrasonic Thickness Testing Work?

An ultrasonic thickness tester works through a short pulse of high-frequency sound being sent through the material you wish to measure. The gauge then measures the time taken for this echo to be received once leaving the back wall of the material and converts it into a distance. This method differs slightly depending on which type of thickness gauge or measuring mode you are using.

There are several benefits to using ultrasonic thickness testing in varying industries, some of which include:

- Non-destructive measuring technique

- Incredible accuracy

- Easy to carry out

- Does not require access to both sides of the material

- And many more!

What UT Thickness Tester Do You Need?

We at Cygnus Instruments realize that there are many different scenarios in which a specific type of thickness gauge is more useful than another. It is for this reason that we cater to all industries and supply ultrasonic thickness testing units that operate in different ways. Depending on what kind of material you’re measuring, certain measuring modes are likely to be better suited to your needs. Below are listed the different measuring modes we offer for our equipment:

Single-Echo

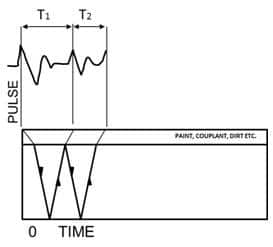

An ultrasonic thickness tester that has a single-echo measuring mode operates by a solitary pulse of sound being sent into a material. Singe-echo gauges, in particular, use a twin crystal probe that is divided into two semi-circular halves. While one sound transmits the single sound pulse, the other receives it. This method does require that any paint or coatings must be removed prior to measuring though or it will be included as well.

Equipment that has a single-echo measuring mode only uses one focused beam, which makes it advantageous when carrying out ultrasonic thickness testing on certain materials. Surfaces that have heavy corrosion on either the front or back walls, such as dredge pipes, benefit from this single beam as reverberation is kept to a minimum. If your business regularly measures material of this type, be sure to take a closer look at our single-echo gauges.

Echo-Echo

The second type of ultrasonic thickness testing gauge that we offer is those with the echo-echo measuring mode. This mode has the same crystal probe as the single-echo models, but the sound pulse that is generated is instead coupled. The receiver then measures the time between the two consecutive echoes and calculates the thickness of the material.

There are many advantages to using a UT thickness tester with an echo-echo measuring mode. One such benefit is that coatings do not need to be removed from these materials as echo-echo can go through coatings up to 1mm in thickness. This measuring mode also has a more focused ‘v-path’ which ensures that a strong signal is received when used on painted metals with corrosion on the back wall.

Multiple-Echo

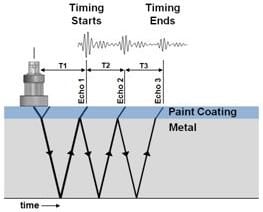

Every ultrasonic thickness tester from Cygnus Instruments has the facility to use the multiple echo measuring mode. Unlike the previous two modes, this measuring method involves the use of a single crystal probe that releases multiple sound pulses into a material. While the beam reverberates up and down within the metal it is measuring, a small portion of energy comes up through the coating. This energy hits the crystal, which now acts as a receiver, and a measurement is taken.

The reason ultrasonic thickness testing is made so much easier with the multiple echo measuring mode is that coating and paint do not have to be removed. Coatings of up to 6mm will be ignored, and with the deep coat function, this can be increased up to 20mm. The single crystal probe also means that the multiple echo measuring mode can be used to measure curved surfaces. Overall, the multiple echo mode allows for a more versatile piece of equipment.

Why Choose Us For a UT Thickness Tester?

We realize how essential ultrasonic thickness testing can be to businesses and are therefore passionate about continuing to progress within the industry. For example, the multiple echo measuring technique, which has proved so effective for so many companies, was developed and pioneered by us at Cygnus Instruments. This innovation shows our commitment to making ultrasonic thickness gauges the best they can be.

If you choose to buy a UT thickness tester with us, you will also benefit from some unique features that are exclusive to Cygnus Instruments’ equipment. Our echo-echo measuring mode benefits from the MSI measurement stability indicator, which ensures only stable measurements are displayed. Functions such as these go lengths to proving that ours is some of the most reliable equipment in the industry.

What Else Can Cygnus Instruments Offer You?

At Cygnus Instruments, we believe in providing our clients with excellent service as well as fantastic products. Our team are determined to exceed your expectations at every turn and will work tirelessly to ensure your total satisfaction. Matters such as reliable shipping and open customer dialogue are crucial to us. We feel that our commitment to our clients is another reason why we are a cut above similar companies that deal in ultrasonic thickness testing equipment.

Over the years, we have assisted businesses in finding the right ultrasonic thickness testing equipment for them. Our practical and straightforward approach has led to many clients leaving us positive testimonials of our service. These comments can be read on our ‘customer reviews’ page, where you will get a better idea as to why they were so impressed with our services. Browsing through this feedback will give you an idea of what to expect from our team.

Overall, you can rely on us at Cygnus Instruments to always deliver quality service and products for ultrasonic thickness testing.

- High-Quality Products

- The Latest Technology

- A Broad Range of Equipment

- Excellent Customer Service

Contact Us Now For a High-Quality Ultrasonic Thickness Tester

So, if you’re convinced that we at Cygnus Instruments are the perfect choice for ultrasonic thickness testing equipment, be sure to get in touch with us today. Our team are always willing to discuss our products in more detail, so if you have any questions, be sure to give us a call. You can reach us now by calling +1 410-267-9771 or can send us an email at sales@cygnusinstruments.com. We’ll be sure to get back to you as soon as possible.